SHANDONG CENTURY MACHINERY CO,.LTD. Intelligent die-cutting line

SHANDONG CENTURY MACHINERY CO,.LTD.

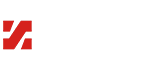

Intelligent die-cutting line

---The efficient engine of the new era of post-print packaging

Driven by the rapid development of modern commerce and logistics, global demand for carton packaging is steadily increasing. The booming e-commerce industry has led to a sharp increase in demand for product packaging, while the thriving logistics industry has also driven a continued increase in carton usage. This shift in the market environment has placed higher demands on carton production efficiency and quality.

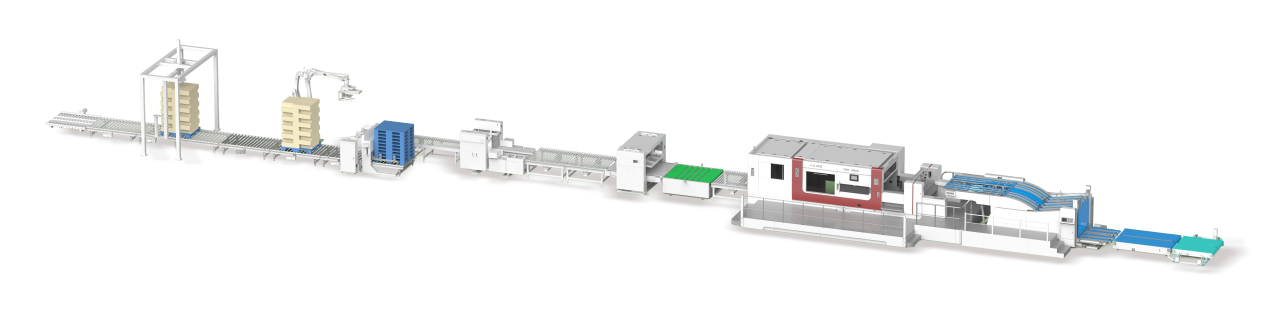

At the same time, the manufacturing industry is undergoing a profound transformation towards intelligent manufacturing. Strategies such as "Made in China 2025" have charted the course for the development of intelligent industry. More and more companies are adopting automated and intelligent equipment to improve production efficiency, reduce labor costs, and enhance market competitiveness. Against this backdrop, carton machinery and production lines are increasingly moving towards standardization, intelligent manufacturing, and online operations. Traditional stand-alone production models rely on manual operations for material loading and unloading, as well as process flow, resulting in significant labor costs and low production efficiency. Intelligent, online equipment, on the other hand, enables seamless integration of multiple processes, automating processes such as loading, die-cutting, sheeting, packaging, and palletizing.

Founded in the corrugated packaging industry, SHANDONG CENTURY keenly grasped this market trend and the need for industry transformation. By integrating post-press processes, it pioneered and developed multiple intelligent post-press production lines in China. Century Machinery's intelligent die-cutting line emerged precisely in this era. It not only aligns with the concept of intelligent manufacturing but also addresses efficiency, cost, and quality challenges for carton manufacturers, becoming a key force in driving industry transformation and upgrading.

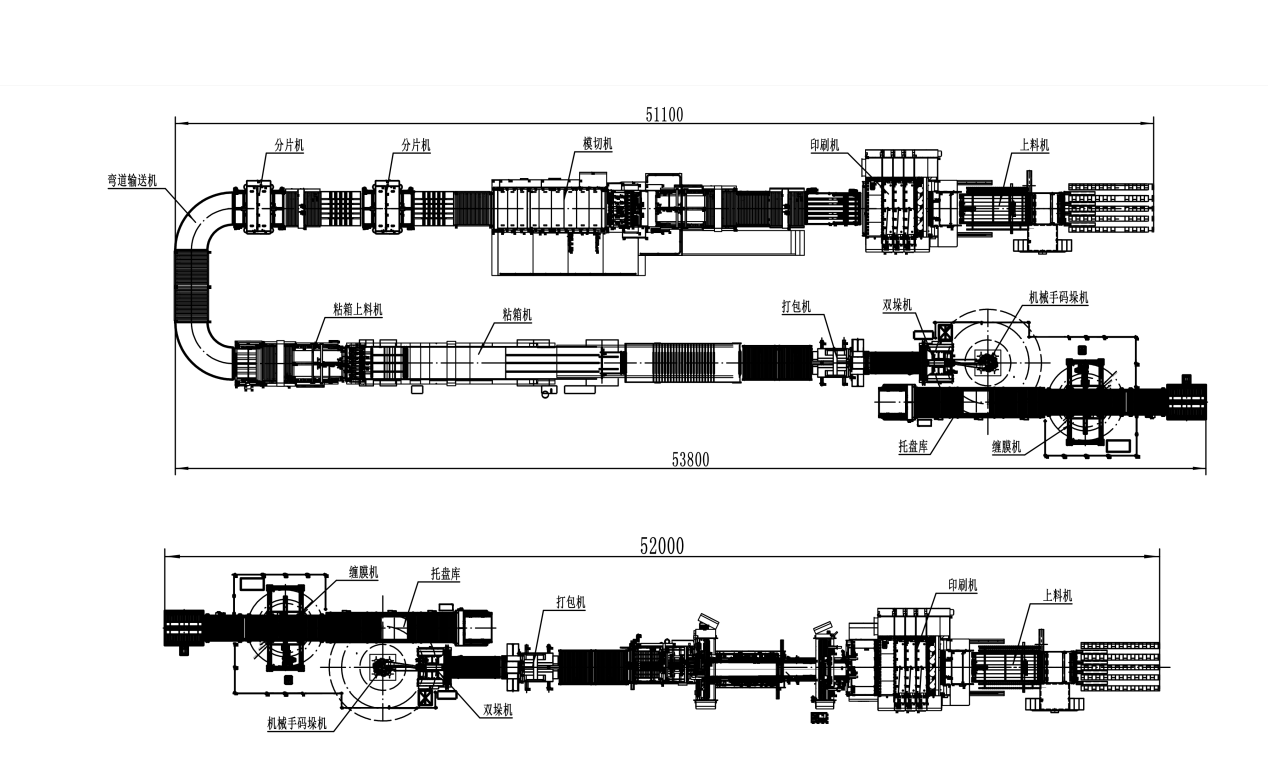

The automatic loading and feeding system is the starting point for continuous production. This mechanical system automatically separates and feeds raw materials (paper, cardboard, etc.) without manual interruption, ensuring continuous material flow. The system automatically adjusts the feeding frequency based on the speed of back-end processes (such as die-cutting and printing), eliminating issues such as slow front-end feeding slowing down overall production or excessive feeding causing material backlogs. This ensures consistent rhythm across all production lines and maximizes overall production capacity.

One automatic loading system can replace two to three workers (traditional loading systems require dedicated personnel to arrange, refill, and organize materials). This significantly reduces labor costs in the long term, making it particularly suitable for companies facing current challenges in recruiting workers and rising labor costs. It also reduces labor intensity and safety risks: Manual loading requires frequent bending and handling (especially for large cardboard and heavy materials), which can easily lead to occupational injuries such as lumbar muscle strain. An automatic system can automatically lift and transport heavy materials, eliminating manual contact with moving parts and minimizing operational safety hazards.

As a core component of automated production lines, automatic loading and paper feeding systems offer advantages in improving production efficiency, ensuring operational stability, reducing costs, and optimizing the production experience.

They facilitate intelligent management and are well-suited to the needs of modern factories.

·Data-based monitoring and traceability: The system can be connected to production line management systems (such as MES) to provide real-time feedback on data such as material loading volume, paper feed speed, and fault warnings. This helps managers understand production progress and predict material consumption (e.g., "remaining materials can support 2 hours of production"), facilitating advance material preparation.

SHANDONG CENTURY flatbed die-cutting system - professional equipment for box forming.

The core function of a die-cutter is to transform cartons from cardboard into finished blanks through four process areas: paper feeding, die-cutting, waste removal, and paper collection. A deeper understanding of a flatbed die-cutter can be gained from the following aspects.

1. High Processing Precision Ensures Consistent Carton Dimensions

Die-cutters utilize servo motors and precision positioning components to achieve high positioning accuracy, ensuring uniform dimensions of carton length, width, height, and folding edges. This advantage is crucial for carton assembly (such as box body fastening and bottom/flap sealing)—consistently sized cartons prevent damage caused by looseness during transportation and are compatible with automated carton sealers and other downstream equipment, reducing manual adjustment costs.

2. Stable Indentation Improves Carton Folding Quality

Manual indentation or simple equipment can easily result in indentations that are too shallow (cracking during folding), too deep (damaging the cardboard), or misaligned (distorted after folding). Die-cutters, on the other hand, utilize adjustable pressure indentation wires to precisely control indentation depth based on cardboard thickness (e.g., 3-ply vs. 5-ply corrugated paper), ensuring neat, secure folded edges and corners. These machines are particularly suitable for processing a wide variety of corrugated cartons, such as those used for logistics packaging. 3. High Efficiency, Suitable for Mass Production

High-speed die-cutting machines (such as flatbed die-cutters) can achieve processing speeds of 100-150 sheets per minute, far exceeding manual processing (40-50 sheets per minute). Features like automatic waste removal and automatic paper ejection reduce manual intervention, enabling "continuous production" and meeting the high-volume order demands of industries like e-commerce and logistics (e.g., tens of thousands of cartons per day), significantly reducing unit production costs.

4. High Flexibility, Suitable for Small-Batch and Customized Production

The core consumable of a die-cutting machine is the die-cutting plate (steel blade). Changing the die-cutting plate with different patterns/sizes takes only 10-30 minutes, enabling rapid switching to produce different sizes of cartons (such as express boxes, food boxes, and custom-shaped boxes). This advantage perfectly matches the current trend toward small-batch, high-variety packaging (such as customized packaging for e-commerce brands), avoiding the pain points of traditional equipment, such as slow changeovers and high costs.

5. Wide range of materials, covering various carton types.

Die-cutting machines can process a variety of cardboard materials, including ordinary cardboard (such as gift boxes), single-layer corrugated paper (such as lightweight packaging), and multi-layer thick corrugated paper (such as heavy-duty logistics boxes). They are also compatible with specialized materials such as coated and laminated paper, meeting the performance requirements of carton boxes in different scenarios (such as moisture resistance and load-bearing).

6. Integrated processing reduces process connection costs.

Some die-cutting machines integrate functions such as waste removal and partial embossing, completing the "die-cutting - creasing - waste removal" process in one stop. This eliminates the need for manual waste removal or transfer to other processing equipment, shortening the production process and reducing intermediate losses (such as rework caused by residual waste).

7. Intelligent upgrades for higher efficiency.

All format adjustments eliminate the need for individual manual adjustments; the entire machine can be adjusted with one click. Secondary production can be started in just 10 minutes.

Slicing system-a powerful tool for cutting multiple finished products

In a die-cutting production line, the slitter is a key piece of equipment responsible for slitting large sheets of die-cut materials (such as paper, film, stickers, leather, etc.) into small sheets or single products of specified specifications. Its core function is to connect the die-cutting process with subsequent processing (such as stacking, packaging, etc.) to achieve automated continuous production.

The core components include:

1. Feeding Mechanism: A conveyor belt smoothly transports die-cut large sheets of material to the slitting area. A rotating mechanism in the middle ensures accurate and smooth material delivery.

2. Slitting Actuator: The motor's rotation drives the slitting blades to slit the product. The product can slit products up to 350 x 300.

3. Separating Mechanism: PLC-controlled, it quickly and regularly transports the product to the next process.

The use of a slitting machine reduces labor costs and waste. Automated slitting eliminates manual operations (such as cutting and sorting), reducing labor costs and avoiding material waste (such as cutting deviations and breakage) caused by manual operations. This improves material utilization and product yield. It also offers stable and reliable operation, facilitating integrated management. The equipment operates stably with a low failure rate. The control system can be integrated with production line management systems (such as MES) to enable real-time monitoring and traceability of production data (output, yield, parameters, etc.), facilitating production scheduling and quality control.

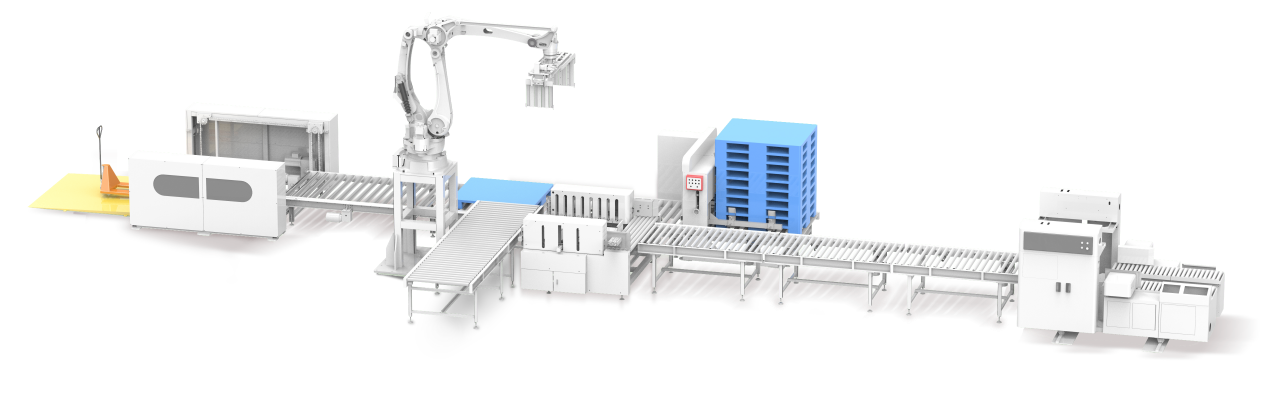

Palletizing system-the origin of robotic palletizing.

CENTURY MACHINERY, committed to being a leading global provider of post-print packaging solutions, introduced robotic palletizing and integrated production lines to the packaging market in 2015.

The robotic palletizing system is highly intelligent, enabling a variety of palletizing configurations through the use of different grippers. Twelve basic pallet configurations are pre-installed, and additional pallet configurations can be added later based on customer product needs. Palletizing is flexible, simple, and low-maintenance. Market-leading palletizing speeds of 12-20 packs per minute have been achieved, depending on the product.

The palletizing system, combined with a pallet storage system, automates the loading and unloading of pallets, completely eliminating human intervention.

The integrated production line features a modular design and can be integrated with multiple production processes, including balers and wrappers. Centralized management of the entire line eliminates the need for frequent adjustments to multiple processes and equipment.