Les matériaux épais comme le cuir, la mousse ou le caoutchouc sont plus difficiles à découper et nécessitent beaucoup de travail. Ce processus est simplifié et accéléré grâce à une machine de découpe à platine. La machine à forage remonte à l'Égypte ancienne, qui utilisait une technique de pointe et de bâton, cependant, nous savons que grâce à cet art du soudage, une machine de découpe remonte au 19ème siècle. Bien que ces deux appareils puissent sembler opposés, ils sont en réalité similaires dans leur histoire. CENTURY Machine de découpe automatique se révéleront inestimables si révolutionnaires sur le fond. Profitez simplement de chaque électrique, un autre découpeur inclut des avantages commerciaux distincts, mais fondamentalement, chaque catégorie peut aider tous les fabricants de procédés, même lorsqu'il s'agit de trouver leurs produits chimiques en coupant simplement des matériaux directement à la silhouette requise. Les machines de découpe par plaquette sont l'un des meilleurs outils pour transformer votre produit en une forme unique lorsque des précautions supplémentaires sont nécessaires. Elles sont également capables de découper plusieurs matériaux, ce qui signifie qu'elles peuvent traverser plus d'une couche de matériaux en même temps. Cela vous fait non seulement gagner beaucoup de temps, mais demande aussi bien moins d'efforts. Que vous créiez des portefeuilles en cuir à la mode ou des inserts en mousse pour l'emballage, des pièces en caoutchouc pour machines et autres accessoires — cette machine accomplira le travail rapidement et efficacement.

Les machines de découpe par plaquette sont excellentes car elles peuvent accomplir beaucoup de choses. En prenant en charge diverses tâches, elles peuvent être très utiles pour vos besoins de production. Vous aurez besoin de différents types de matrices de découpe pour créer des formes et des designs uniques sur vos produits. Une matrice de découpe est une plaque métallique avec des bords tranchants conçus pour découper le matériau. Une fois que vous avez identifié la matrice idéale pour votre produit, il est simple de produire rapidement de nombreuses formes identiques. Machines de Découpe par Plaquette : Ces machines de découpe par plaquette découpent de nombreux matériaux différents tels que le papier, le tissu, le cuir, la mousse ou le caoutchouc. Autrement dit, vous pouvez personnaliser votre chaîne de montage pour qu'elle corresponde au mieux à vos besoins. Peu importe si vous fabriquez un emballage personnalisé, des garnitures de meubles ou des jouets amusants ; cette machine peut être utile lors de la création de quelque chose d'unique qui se distingue du reste du marché.

Ces machines sont incroyablement précises. Elles vous permettent de créer des coupes nettes avec des angles droits et beaucoup de détails. Cette CENTURY, Machine de découpe semi-automatique la précision garantit que chaque coupe correspond aux spécifications de votre conception, donc vous obtenez exactement ce qui était prévu, sans imperfection due à l'erreur de la machine ou humaine. De plus, la technologie utilisée dans les machines de découpe par platen maintient la lame affûtée pendant le processus de découpe réel. Cela aide à minimiser le risque de déchirures ou de dommages aux matériaux que des techniques de découpe moins précises peuvent parfois causer.

La découpe au forme est un grand avantage pour la plupart des entreprises, et si elle est réalisée en découpe automatisée, elle améliorera votre processus de production. L'utilisation d'une machine de découpe par platen permet aux entreprises d'automatiser le processus fastidieux de découpe des matériaux, économisant ainsi du temps et de l'argent. Nous avons modernisé ces cellules de découpe avec de l'automatisation pour réduire le travail manuel et éviter que le processus de découpe ne devienne un facteur limitant dans notre chaîne de production, car certains processus manuels peuvent être lents ou incohérents.

En utilisant une machine de découpe automatisée à platine, vous pouvez produire une grande quantité de formes et de conceptions identiques en un minimum de temps. Avec ce niveau d'efficacité, vous traiterez les grandes commandes en peu de temps, améliorant ainsi votre productivité totale. CENTURY Machine de découpe d'occasion libère également votre personnel pour qu'il puisse s'occuper d'autres tâches au lieu de faire fonctionner la machine pendant de longues périodes, ce qui augmente indirectement la productivité et, à terme, le profit.

L'entreprise est attentive au service après-vente et a créé un système complet de services post-vente capable de répondre aux besoins des clients en temps opportun, de fournir aux clients des services de formation qualifiée et d'entretien des machines de découpe à plat et de résoudre les préoccupations des clients. L'entreprise dispose d'une forte capacité en R&D et est le seul "Centre de Recherche et Développement des Technologies Platiales Chinois" certifié par l'Association du Conditionnement et de l'Imprimerie du Shandong. En investissant continuellement dans les fonds de R&D, en mettant en œuvre l'innovation technologique et la mise à niveau des produits, nous pouvons fournir aux clients les technologies et produits les plus récents.

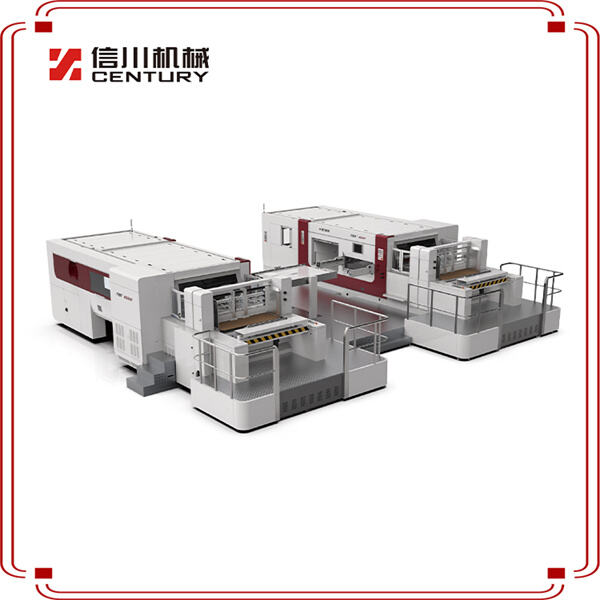

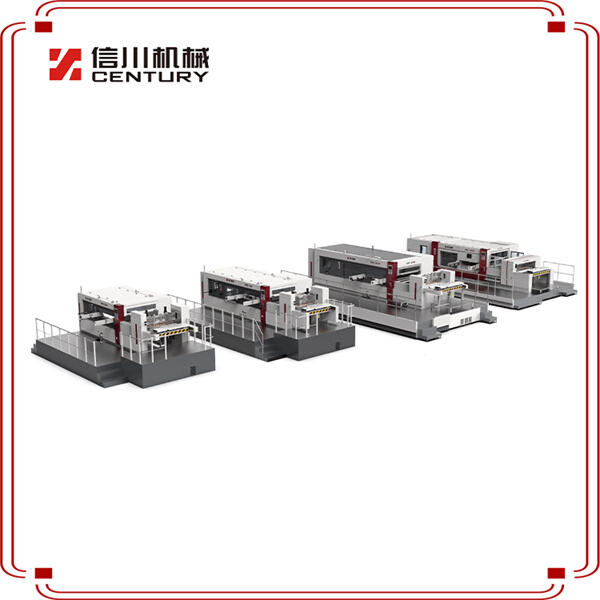

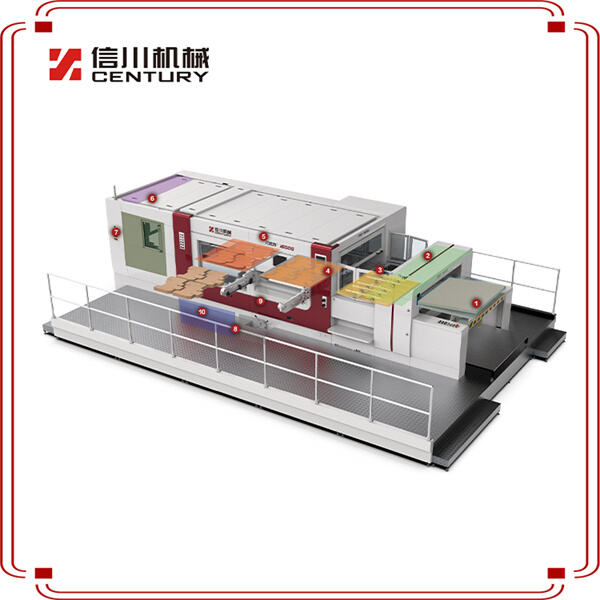

La machine de découpe au plat de CENTURY est capable de découper du carton ondulé, ainsi que d'autres matériaux. Elle peut être utilisée à diverses fins et répondre aux besoins de nombreux clients. Pour garantir une précision dans la découpe, cet équipement est fabriqué avec des matériaux de haute qualité et des technologies modernes, y compris un engrenage à haute résistance et un mécanisme précis pour saisir le papier. La pression utilisée pour découper le papier est uniforme, ce qui réduit l'usure des plaques de découpe et assure une précision et une longue durée de vie. Certains modèles peuvent atteindre une vitesse maximale de 7 500 feuilles par heure, avec une efficacité opérationnelle élevée, et peuvent être couplés avec des équipements prépresse pour améliorer l'efficacité globale de production. La dernière technologie de découpe automatisée intelligente à alimentation automatique de papier représente une avancée technologique majeure, entièrement conçue pour l'automatisation, améliorant ainsi l'efficacité de production, la qualité du carton utilisé et la sécurité.

Shandong Century Machinery Co., Ltd. a été fondée en 2008. Elle est certifiée CE et certifiée pour les machines de découpe à plat. C'est une entreprise provinciale ultramoderne ainsi qu'une entreprise "petit géant" spécialisée au niveau national. Elle jouit d'un bon niveau de reconnaissance et de réputation dans le secteur. L'entreprise compte plus de 50 chercheurs scientifiques professionnels et dispose d'une équipe solide en R&D et en production pour garantir la qualité et l'efficacité de ses produits. Les produits de l'entreprise sont bien vendus dans 29 provinces, municipalités et régions autonomes de Chine, et exportés vers plus de 60 pays, y compris le Royaume-Uni, la Turquie, le Japon, etc. L'entreprise possède un grand marché et une large base de clients. Les produits de l'entreprise sont appréciés par les clients internationaux et nationaux.

Nous développons et améliorons constamment nos produits et avons lancé une gamme de produits distincts. Par exemple, la machine à alimentation de papier de type cassette utilise des mouvements ponctuels vectoriels de la "machine de découpe Platen" pour alimenter le papier, sans frottement et sans déplacement, ce qui résout le problème des rayures sur la surface imprimée ; la méthode de jauge poussant vers la gauche et la droite du pont répond aux exigences des différents enregistrements d'impression et assure un positionnement précis du carton. Il existe une large gamme de modèles de produits, tels que 930, 1050, 1160, 1300, 1450, 1620, et ainsi de suite, pour les produits semi-automatiques et 1050, 1080, 1450, 1650, et ainsi de suite, pour les produits entièrement automatiques, et peut s'adapter aux capacités de production et aux besoins en processus de divers clients. Lorsqu'on la compare aux équipements importés, la machine de découpe plate de CENTURY Machinery présente des avantages évidents en termes de prix. Les performances et la qualité du produit sont capables de répondre aux exigences des clients, tout en étant économiques.