Découpe au format plat, en avez-vous déjà entendu parler ? C'est un passe-temps, mais aussi une méthode intéressante pour découper des formes dans une variété de matériaux. Dans cet article, nous explorerons la découpe au format plat, ce qui la rend avantageuse pour divers types d'entreprises, ainsi que la gamme de matériaux pouvant être utilisés pour obtenir vos formes souhaitées, avec quelques conseils utiles pour réaliser des coupes parfaites et comment engager un prestataire de services professionnel expérimenté. Plongeons-y !

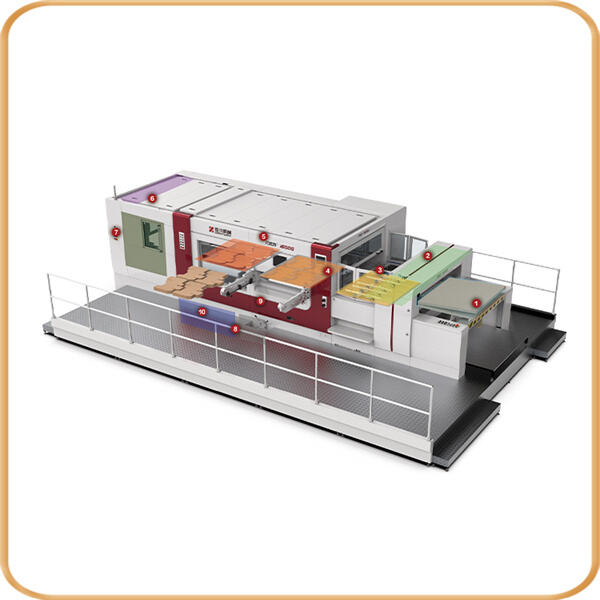

Découpe au format plat : La découpe au format plat est une forme propriétaire de découpe de matériaux plats. Ce procédé du XXe siècle nécessite une machine massive appelée presse et un outil de frappe. L'outil — est une plaque métallique avec des bords tranchants. Avec la presse forçant l'outil dans le matériau, elle coupe efficacement et forme la shape désirée. Comme utiliser un emporte-pièce pour découper des cookies ; le Machine de découpe outil le fait avec du papier ou du plastique !

Il existe plusieurs avantages du découpage au couteau sur presse plat pour les entreprises cherchant à créer des matériaux personnalisés. L'un des bons aspects est qu'il offre une découpe précise. Les mêmes formes sont découpées à chaque fois, et c'est ce type de cohérence dont les entreprises ont besoin. Il économise également beaucoup de temps par rapport à la découpe manuelle. En combinaison, ils peuvent concevoir de nombreuses formes possibles, permettant aux entreprises de fabriquer des produits distinctifs qui sont uniques et attractifs. Avoir un point de différence et quelque chose de spécial à offrir peut aider à attirer les clients !

Il existe presque un nombre incalculable de matériaux que le découpage par matrices sur une presse à plat peut gérer. Par exemple, le papier, le carton et les plastiques, les matériaux en cuir et les matériaux en mousse ainsi que d'autres types de métaux. Chaque matériau sera différent et nécessitera un type de matrice spécifique pour être découpé correctement. Il existe des matrices très fines et tranchantes pour le papier et le carton, mais aussi des matrices extrêmement épaisses et lourdes (dures). Cette CENTURY peut être utilisée pour transformer une simple feuille de base en une forme esthétique, artistique et utilisable grâce au découpage par matrices sur une presse à plat. Ces Machine de découpe d'occasion formes servent diverses fonctions telles que l'emballage, les panneaux, les étiquettes ou encore les affichages, etc. C'est fascinant de voir comment quelque chose de si petit peut se transformer en quelque chose de si créatif.

Réglez l'orifice selon votre matériau spécifié et la pression de la matrice, puis ajustez également la vitesse de la presse avec une touche de profondeur. Les paramètres de CENTURY peuvent varier pour chaque combinaison possible de paramètres. Machine de découpe semi-automatique à bien vérifier ceux-ci. Ajustez les

Premiers coupes effectuées. Machine de découpe automatique réglages à adapter ou répéter si cela semble incorrect et que vous n'obtenez rien d'utile de votre haut-parleur externe.

Il est très important de choisir un service de découpe au format plat approprié pour de bons résultats. Si vous cherchez à obtenir une assistance, trouvez des expériences pratiques fantastiques ! Vous voudrez que vos attentes soient surpassées par leurs machines bien conçues qui peuvent travailler avec différents matériaux et designs. Vous pouvez également consulter leurs prix, délais de réalisation et ce que les clients en pensent. Le Ligne d'emballage intelligente CPU service doit toujours s'assurer de placer vos exigences en première priorité, proposer de bonnes solutions et fournir des produits excellents qui correspondent à ce que vous attendez d'eux.

L'entreprise propose des services allant de la découpe au format plat jusqu'au service après-vente et a développé un système de support après-vente capable de répondre rapidement aux besoins des clients, en leur offrant une assistance technique qualifiée et efficace ainsi que des services de maintenance. Elle aide également à résoudre les préoccupations des clients. L'entreprise se distingue par une impressionnante capacité en R&D et est le seul "Centre de Recherche et Développement en Technologie Plat" chinois reconnu par l'Association de l’emballage et de l'impression du Shandong. Grâce à un investissement continu en R&D, nous pouvons fournir à nos clients des produits et solutions avancés grâce à l'innovation technologique et à l'amélioration des produits.

Shandong Century Machinery Co., Ltd. a été fondée en 2008. L'entreprise est certifiée pour l'impression offset et ISO9001. C'est une entreprise locale de haute technologie, ainsi qu'une entreprise nationale spécialisée qualifiée de "petit géant". C'est une société qui jouit d'une grande reconnaissance et d'une bonne réputation dans le domaine. Elle compte plus de cinquante scientifiques professionnels et une solide équipe de production et de R&D. Cela garantit la qualité et les performances. Les produits de l'entreprise sont largement distribués dans 29 provinces, villes et régions autonomes de Chine, ainsi que出口és vers plus de 60 pays, y compris le Royaume-Uni. L'entreprise dispose d'une base client et d'un marché substantiels. Les produits de l'entreprise sont appréciés par les clients tant à l'échelle nationale qu'internationale.

Nos produits ont fait l'objet d'innovations et d'améliorations constantes. Nous avons également lancé une variété de produits innovants. Par exemple, le découpage à plat utilise les mouvements vectoriels du "point zéro" pour alimenter le papier sans frottement et sans déplacement, ce qui résout le problème des rayures sur la surface imprimée. L'écartmètre gauche et droit du composant pont permet de répondre aux exigences des différents enregistrements d'impression et assure un positionnement précis du carton. La gamme de produits inclut 930, 1050, 1150, 1300, 1450, 1620 et 1620. Les modèles semi-automatiques sont 1050, 1080, 1450, 1650, etc. Les produits entièrement automatisés peuvent être modifiés pour répondre aux besoins des clients. Les machines de découpe à plat CENTURY sont moins coûteuses que les modèles importés. Cependant, leur qualité et leurs performances répondent également aux besoins des clients, avec un excellent rapport qualité-prix.

La machine à plat de CENTURY pour le découpage par matrices peut découper non seulement du carton ondulé, mais aussi du carton et d'autres matériaux. Elle peut être utilisée à diverses fins et répondre aux besoins de nombreux clients. L'équipement utilise des technologies avancées et des composants de haute qualité, tels que des dents en acier de haute résistance et des mécanismes de maintien du papier précis, garantissant ainsi la précision du processus de découpe par matrices. Les pressions de découpe sont précises et uniformes, ce qui élimine la nécessité de regraver les plaques. Certains modèles peuvent atteindre une vitesse maximale de 7 500 feuilles par heure. Ils sont extrêmement efficaces et peuvent être utilisés en association avec des équipements prépresse pour améliorer l'efficacité de production. Le nouveau système de découpe par matrices automatique et intelligent représente une percée technologique qui a automatisé et amélioré intelligemment l'efficacité de production, la qualité du carton et la sécurité.