Le découpage au châssis à plat peut sembler un peu compliqué, mais c'est en réalité une méthode très simple et efficace pour découper des matériaux tels que le papier, le carton et le tissu. Décortiquons cela ! Cela utilise une lame métallique tranchante appelée châssis pour découper à travers le matériau. Pensez au châssis comme à un instrument spécial conçu pour donner une certaine forme ou motif. de découpe manuelle a lieu sur une surface plane, comme une planche ou une table. La meilleure partie est que lorsque un dé est créé spécifiquement pour la forme que vous souhaitez découper, vous pouvez réaliser toutes sortes de formes et de designs incroyables avec un minimum d'effort.

Cela devient vraiment utile dans le processus d'aplatissement du découpage par matrice plate, si vous êtes impliqué dans la fabrication. découpeur manuel à matrices des produits pour lesquels il faut découper avec précision. C'est comme un superpouvoir pour votre processus de production ! Un découpeur à plat à matrices vous aide à accroître la vitesse opérationnelle de fabrication. Et c'est parce que chaque découpe sera identique et précise, simplifiant ainsi l'assemblage de vos produits par la suite. Et si vous pouviez faire en sorte que toutes les pièces du puzzle s'emboîtent bien ? Cela signifie également que vous n'allez pas gaspiller de matériaux, comme du papier ou du tissu, en jetant des morceaux coupés incorrectement. À long terme, cela vous fait gagner du temps et de l'argent.

Nous pouvons accomplir beaucoup de bonnes choses si nous utilisons la découpe à plat pour nos besoins de découpe. La découpe à plat à matrices a des coupes précises qui sont identiques à chaque fois, avant tout. Cela est très important pour presse de découpe au forme produits qui doivent s'emboîter ou se nester étroitement, comme des pièces de puzzle ou des boîtes. Si les pièces ne s'assemblent pas précisément, cela peut poser des problèmes lorsque vous tentez de les assembler. Un autre point est la flexibilité : l'embossage sur presse plate est très flexible. Cela signifie que vous pouvez l'utiliser pratiquement n'importe où, même sur du papier, du plastique, du métal — peu importe ! Cela crée beaucoup d'opportunités pour ce que vous pouvez construire. Enfin, l'embossage sur presse plate est un processus populaire sur lequel de nombreuses entreprises comptent. Il fonctionnera bien pendant longtemps et vous pouvez vous y fier.

Si votre objectif est d'obtenir ces coupes exactes en utilisant la technologie de découpe au pressoir plat, vous devrez sélectionner le bon moule pour ce projet. Cela signifie utiliser une entreprise comme CENTURY, qui peut fabriquer des moules sur mesure selon vos conceptions exactes. Ils peuvent vous conseiller précisément sur ce dont vous avez besoin pour réussir votre projet. Une fois que vous avez votre moule, vous pouvez poser votre matériau sur le plateau du découpeur. Ensuite, vous faites tomber le moule sur le matériau. Le matériau que vous coupez sera découpé selon la forme souhaitée. Donc, en fonction du niveau de détail ou de la complexité de votre conception, il se peut que vous deviez découper le matériau plus d'une fois pour bien terminer le travail.

Choisir le bon châssis à plat avec le bon poinçon est crucial pour obtenir les résultats souhaités pour votre projet. Si vous constatez que vous avez besoin de quelque chose d'unique, nous pouvons travailler avec vous chez CENTURY pour développer un châssis sur mesure selon vos spécifications. Notre équipe discutera avec vous du matériau à utiliser, de la taille et de la complexité du design, ainsi que de la rapidité dont vous avez besoin. Après cela, nous créerons un châssis qui répond à vos besoins. De cette manière, vous pouvez fabriquer des produits utiles et précieux.

Shandong Century Machinery Co., Ltd. a été fondée en 2008. C'est une entreprise certifiée ISO9001 pour le système de gestion de la qualité et certifiée CE. Elle est une entreprise provinciale de pointe ainsi qu'une entreprise nationale spécialisée dans le domaine du "lit plat à meuler". Elle jouit d'une grande reconnaissance et d'une excellente réputation sur le marché. L'entreprise compte plus de cinquante scientifiques qualifiés, ainsi qu'un solide département R&D et une équipe de production. Cela garantit la meilleure qualité et performance. Les produits proposés par l'entreprise sont bien vendus dans 29 provinces, villes et régions autonomes en Chine, ainsi que出口és vers plus de 60 pays, y compris le Royaume-Uni. Elle dispose d'une large base de clients et d'une vaste base de marché, et ses produits ont été acceptés par les clients tant nationaux qu'internationaux.

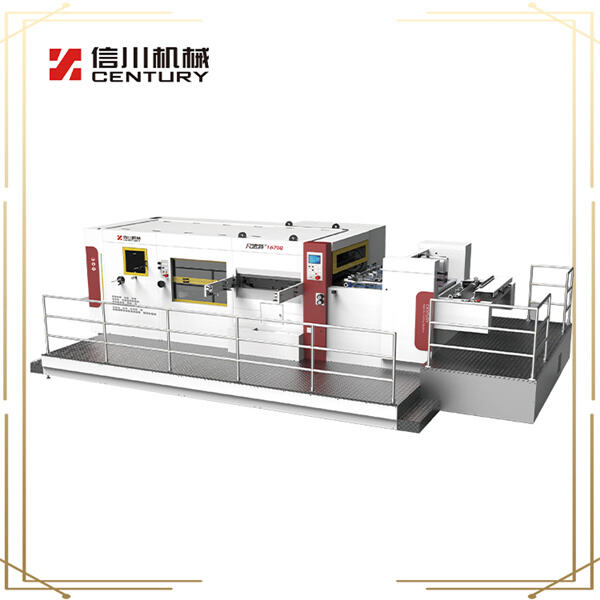

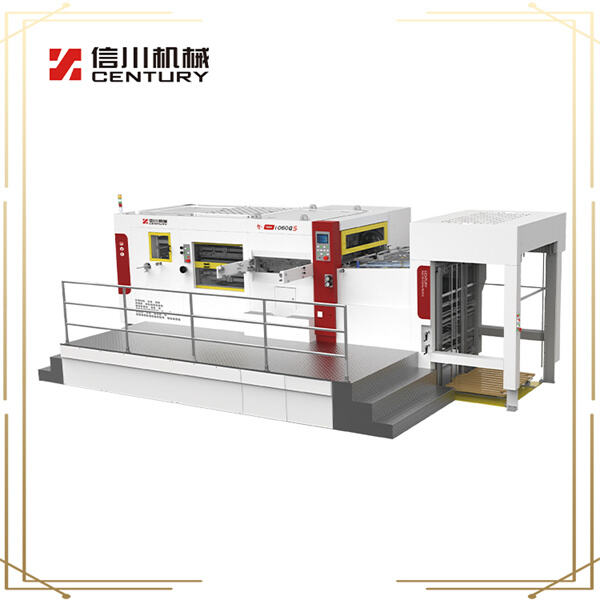

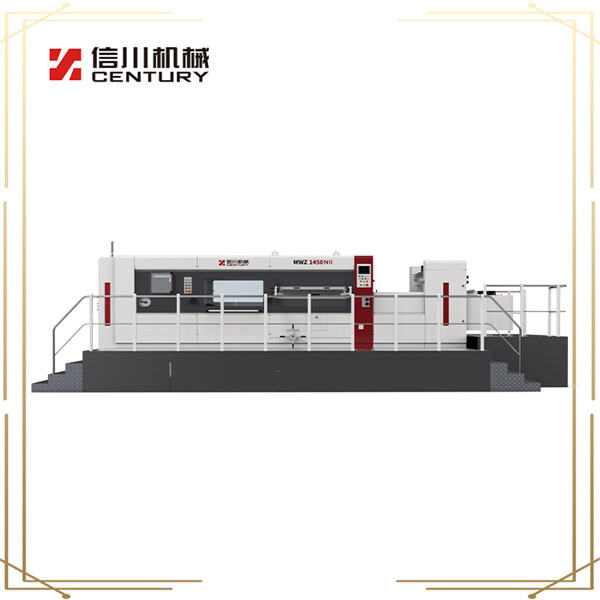

Les machines de découpe à plat de type table de CENTURY sont capables de découper non seulement du carton ondulé, mais aussi du carton et d'autres matériaux. Elles peuvent être utilisées à diverses fins et répondre aux exigences de différents clients. Pour garantir la précision de la découpe, la machine est fabriquée à partir de matériaux de haute qualité et de technologies de pointe, telles que des engrenages à haute résistance et un mécanisme de maintien du papier précis. Les pressions de découpe sont précises sur le lit plat et nécessitent moins de regravure de plaques. Certains modèles peuvent atteindre une vitesse maximale de 7 500 feuilles par heure. Cela représente une efficacité opérationnelle élevée, pouvant être couplée avec des équipements prépresse pour améliorer l'efficacité globale. La nouvelle machine de découpe automatique intelligente à alimentation frontale a réalisé des progrès technologiques en matière d'intelligence et d'automatisation, améliorant considérablement l'efficacité, la productivité, la qualité du carton et la sécurité, ainsi que l'efficacité du changement de commandes.

Nous avons continué à améliorer et à mettre à niveau nos produits, et nous avons lancé plusieurs produits nouveaux et uniques. La machine d'alimentation de papier de type cassette en est un exemple. Elle utilise un mouvement vectoriel "point zéro" pour alimenter le papier avec un minimum de friction et pratiquement aucune déplacement. C'est une solution au problème de rayures sur la surface de l'impression. La gamme de produits inclut 930, 1050, 1160, 1300, 1450, 1620, etc. Les modèles semi-automatiques incluent 1050, 1080, 1450, 1650. Les produits entièrement automatisés peuvent être adaptés pour répondre aux exigences des clients. Les machines de découpe par matrices plates CENTURY sont moins chères que les produits importés. Les performances et la qualité du produit peuvent satisfaire les besoins des clients, tout en étant économiques.

L'entreprise est attentive au service après-vente et a créé un système complet de service après-vente capable de répondre aux besoins des clients en temps opportun, de fournir aux clients des services qualifiés de maintenance des matrices plates et de résoudre leurs préoccupations. L'entreprise possède une forte capacité de R&D et est le seul centre de "Recherche et Développement de Technologie des Matrices Plates" chinois, décerné par l'Association Shandong du Conditionnement et de l'Imprimerie. En investissant continuellement dans les fonds de R&D, en mettant en œuvre l'innovation technologique et la mise à niveau des produits, nous pouvons fournir aux clients les technologies et produits les plus récents.