La découpe sur table plat est une méthode de traitement unique pour découper des formes spécifiques à partir de grandes feuilles de matériau. Cette procédure est effectuée à l'aide d'appareils spéciaux qui sont toujours capables d'effectuer des découpes exactes. Les produits dans de nombreux secteurs industriels (construction automobile, bâtiment, etc.) ainsi que même la fabrication de meubles nécessitent d'être coupés à l'aide de la découpe sur table plat. Cette technologie est incroyablement précieuse pour les entreprises afin de produire efficacement les articles dont elles ont besoin.

Renforcez l'entreprise pour qu'elle travaille mieux et plus vite CENTURY Panneau alvéolaire Le découpage au lit plat, l'une des meilleures parties est publiée. Cette technologie permet aux travailleurs de découper les matériaux rapidement et avec un gaspillage minimum. Ils peuvent faire cela, ce qui résulte en une production accélérée de biens et en économies de coûts. Avec une production rapide et des prix plus bas, ces usines peuvent obtenir un avantage compétitif sur les autres entreprises. Nous sommes dans un marché à fort volume et à rythme rapide, et nous devons tous accomplir notre travail de manière plus intelligente.

L'un des principaux avantages du découpage sur table plat est qu'il permet de découper les matériaux avec une excellente précision. Des bords lisses et nets sont obtenus grâce au découpage précis des matériaux. Cette exactitude est cruciale pour de nombreux produits, en particulier là où l'esthétique et la fonctionnalité doivent être en équilibre. Par exemple, dans l'industrie de la production automobile ; des coupes précises aident à s'assurer que différentes pièces de voiture, comme les joints, s'emboîtent parfaitement ensemble et donnent finalement une apparence sans couture et élégante. Ce n'est pas seulement du point de vue esthétique, mais en même temps, cela garantit que les produits fonctionnent correctement sans aucun problème.

L'usinage sur table plat est également largement connu pour sa convivialité et sa flexibilité. Comparé à d'autres méthodes d'usinage qui sont plus lentes et nécessitent une installation plus difficile, il faut beaucoup moins de temps pour configurer l'usineur sur table plat. C'est un avantage considérable pour les installations de fabrication qui doivent souvent changer de matériaux ou de produits. Sa compatibilité avec les métaux, les plastiques, les tissus et le bois est pratique pour que les usines l'adaptent en fonction de leurs futurs besoins. L'usinage sur table plat offre donc aux fabricants une grande flexibilité.

L'usinage sur table plat a révolutionné la manière dont les produits sont fabriqués dans de nombreuses industries. Cela permet ainsi aux usines de produire des articles visuellement attractifs qui sont non seulement fonctionnels mais aussi séduisants. Le CENTURY Machine de découpe la technologie peut être utilisée pour découper des formes et des dimensions exactes des matériaux dont les fabricants ont besoin. Cela aide à réduire les déchets, à faire des économies et à protéger l'environnement. Si les usines peuvent produire de manière plus efficace, elles sont également en mesure d'augmenter leurs taux de production — ce qui leur permet mieux de répondre à la demande des consommateurs.

Un autre avantage majeur de la découpe sur table est qu'elle peut travailler avec une multitude d'options de matériaux. Les usines peuvent créer des produits allant des métaux solides aux plastiques malléables, en passant par les tissus moelleux ou les bois durs. Sa versatilité la rend parfaite pour les fabricants qui souhaitent créer des produits robustes et esthétiques répondant aux besoins d'une large gamme de clients.

L'avantage indéniable du système de découpe sur table CENTURY Produits est leur précision et qualité exceptionnelles. Ils utilisent les dernières technologies de découpe précise, permettant à ces systèmes de produire des matériaux qui correspondent exactement au design d'origine. Grâce à leur haute précision, le produit final est de très bonne qualité, ce qui compte énormément pour les fabricants qui souhaitent répondre aux besoins de leurs clients. Des services de qualité sont suffisants pour satisfaire les clients, qui reviendront, ce qui est le plus important pour une organisation.

Shandong Century Machinery Co., Ltd. a été fondée en 2008. C'est une entreprise certifiée ISO9001 pour le système de gestion de la qualité et certifiée CE. Elle est une entreprise provinciale de pointe ainsi qu'une entreprise nationale spécialisée dans le domaine du "découpage sur table plat". Elle jouit d'une grande reconnaissance et d'une réputation solide sur le marché. L'entreprise compte plus de cinquante scientifiques qualifiés, ainsi qu'un département R&D et une équipe de production solides. Cela garantit la meilleure qualité et performance. Les produits de l'entreprise sont bien vendus dans 29 provinces, villes et régions autonomes en Chine, et sont également exportés vers plus de 60 pays, y compris le Royaume-Uni. Elle dispose d'une large base de clients et d'une vaste base de marché, et ses produits ont été acceptés par les clients tant à l'échelle nationale qu'internationale.

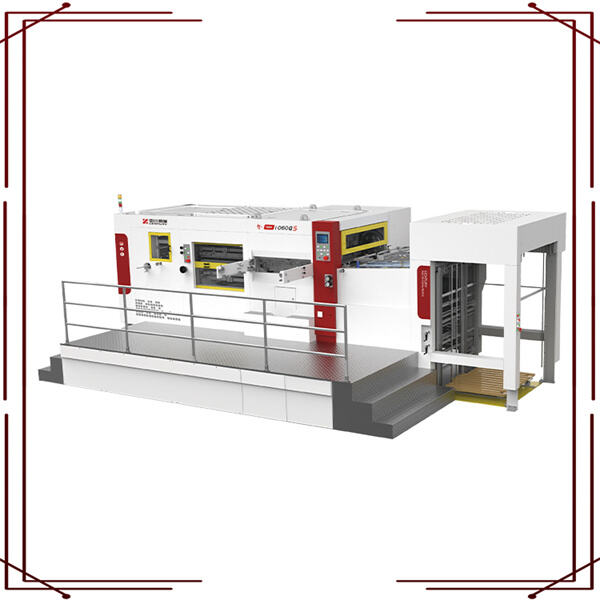

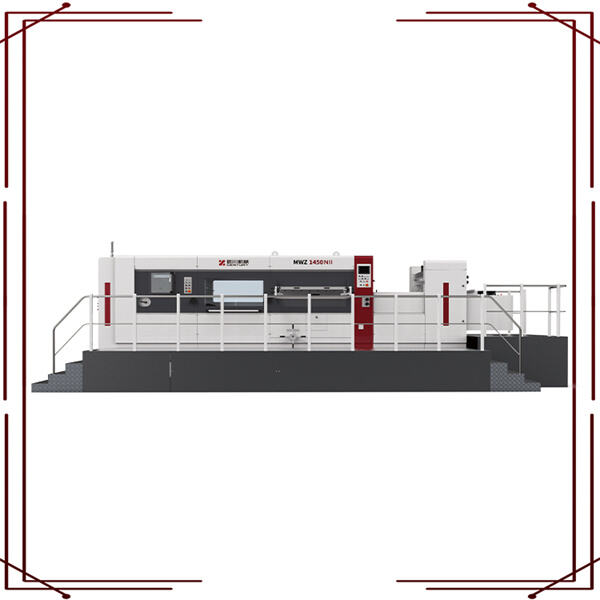

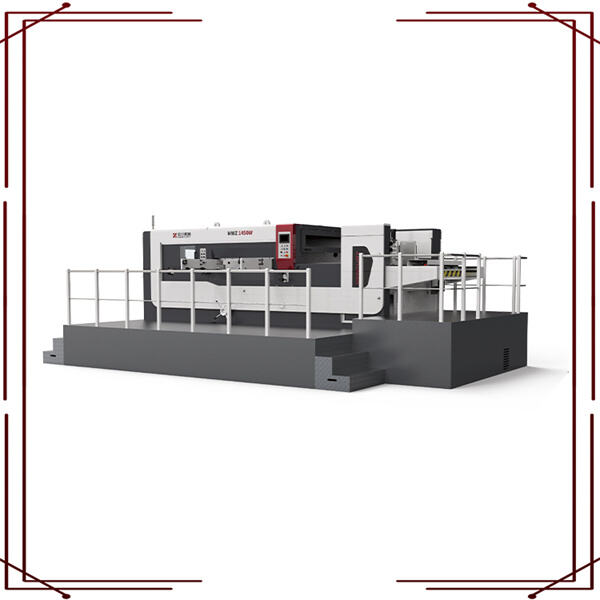

La machine de découpe par matrices plates de CENTURY peut non seulement découper du carton ondulé, mais elle peut également découper du carton et d'autres matériaux. Elle offre une large gamme d'applications pouvant répondre aux exigences de différents clients. L'équipement utilise des technologies avancées et des composants de haute qualité, y compris des engrenages à haute résistance et des mécanismes précis pour la prise en charge du papier, afin d'assurer l'exactitude du découpage. Les pressions de découpe sont précises et uniformes, avec peu de besoin de regraver les plaques. Certains modèles peuvent atteindre une vitesse maximale de 7 500 feuilles par heure. Elle présente un taux de travail efficace et peut être couplée avec des équipements prépresse pour améliorer l'efficacité globale de production. La nouvelle machine de découpe automatique intelligente à alimentation avant a réalisé des progrès technologiques en matière d'automatisation et d'intelligence en ce qui concerne l'efficacité de production, la qualité du carton et la garantie de sécurité, ce qui améliore considérablement l'efficacité de production des commandes de découpe plate.

Nous avons continué à découper au lit plat et à améliorer nos produits, et nous avons lancé plusieurs produits nouveaux et uniques. L'exemple est la machine à alimentation de papier de type cassette. Elle utilise un mouvement vectoriel "point zéro" pour alimenter le papier avec une friction minimale et pratiquement aucun déplacement. C'est une solution au problème de rayures sur la surface de l'impression. La gamme de produits inclut 930, 1050, 1160, 1300, 1450, 1620, etc. Les modèles semi-automatiques incluent 1050, 1080, 1450, 1650. Les produits entièrement automatisés peuvent être adaptés pour répondre aux exigences des clients. Les machines de découpe au lit plat de CENTURY Machinery sont moins chères que les produits importés. Les performances et la qualité du produit peuvent satisfaire les besoins des clients, tout en étant économiques.

L'entreprise se concentre sur le support après-vente et a mis en place un système complet d'assistance après-vente capable de répondre aux besoins des clients en matière de découpe au lit plat, et offre aux clients un soutien technique professionnel et efficace ainsi que des services de maintenance. Ils éliminent également les inquiétudes des clients. L'entreprise est le seul "Centre RD de Découpe au Lit Plat" en Chine reconnu par la Fédération Chinoise de l’Emballage et le "Centre Technologique RD Shandong pour la Découpe au Lit Plat" décerné par l'Association de l’Emballage et de l’Imprimerie du Shandong, avec de fortes capacités en Recherche et Développement. En investissant continuellement dans les fonds de R&D, en mettant en œuvre des progrès technologiques et en améliorant les produits, nous sommes en mesure de fournir aux clients des technologies et produits de pointe.