Dans toutes les conversations sur l'emballage, qu'y a-t-il au-delà de ce que nous voyons à la surface ? Chaque CENTURY machine de découpe et d'embossage nous achetons possède une boîte ou un contenant exclusif qui le protège. Le produit doit être emballé selon les bonnes spécifications. Ainsi, ces conteneurs sont conçus pour s'adapter parfaitement au produit et faciliter sa manipulation par les personnes.

Les découpes de boîtes (fabriquées en carton ondulé) rendent la production de boîtes beaucoup plus facile et rapide. Ces CENTURY machine de découpe et d'embossage sont capables de découper plusieurs morceaux de carton en même temps, ce qui est un gain de temps énorme. Cela est particulièrement utile si une entreprise a besoin de beaucoup de boîtes rapidement. Un problème courant avec les commandes fractionnées est d'avoir certaines boîtes plus grandes que d'autres.

En plus de l'esthétique, CENTURY machine de découpe et d'embossage économiser les matières et réduire les déchets. Moins de carton résiduel signifie moins de matériau nécessaire pour les emballages conçus spécifiquement pour le produit. Ils sont également suffisamment solides pour ne pas nécessiter de matériaux supplémentaires, tels que du film plastique ou du ruban adhésif. Les entreprises économisent de l'argent et des ressources en produisant des boîtes résistantes et autonomes.

Les boîtes personnalisées peuvent également aider une entreprise à mettre en avant sa marque. Les clients se souviennent d'un produit avec des designs et des couleurs spéciaux. Logo, slogan percutant, couleur vive et tout ce qui se trouve entre les deux pour attirer l'attention des gens. Si un CENTURY presse de découpe au forme a une apparence distinctive, il peut laisser une impression durable sur une marque auprès du marché. En fin de compte, une identité de marque forte permet aux clients fidèles de revenir encore et encore pour acheter leur produit préféré.

Beaucoup plus de gens aiment CENTURY presse de découpe au forme et souhaitent acheter des produits respectueux de la planète. Il est fabriqué à partir de ressources renouvelables et est recyclable, donc le carton ondulé est une excellente option. Ainsi, lorsque nous utilisons du carton pour fabriquer des boîtes, nous travaillons avec un matériau qui peut être réutilisé encore et encore.

L'entreprise se concentre sur le support après-vente et a mis en place un découpeur de cartons ondulés capable de répondre aux besoins des clients de manière rapide, tout en offrant un soutien technique professionnel et efficace ainsi que des services de maintenance, résolvant ainsi les préoccupations des clients. C'est le seul "Centre RD de Découpeuse Plateforme" en Chine reconnu par la Fédération Chinoise de l’Emballage et le "Centre RD de Technologie Plateforme de Shandong" certifié par l'Association de l’Emballage et de l’Imprimerie de Shandong, avec une capacité à mener des activités de recherche et développement à un niveau élevé. Nous pouvons fournir à nos clients des produits et solutions avancés grâce à des investissements continus dans la R&D, à la mise en œuvre d'innovations technologiques et à la modernisation des produits.

Shandong Century Machinery Co., Ltd. a été fondée en 2008. C'est une entreprise certifiée par le système de gestion de la qualité ISO9001 et certifiée CE. C'est également une entreprise de découpe de cartons ondulés dans la province et elle est considérée comme une "petite géante" spécialisée au niveau national. Elle jouit d'une grande reconnaissance et de respect dans l'industrie. Elle compte plus de cinquante scientifiques qualifiés, ainsi qu'une solide équipe de production et de R&D. Cela garantit la qualité et l'efficacité. Les produits de l'entreprise sont distribués efficacement dans 29 provinces, municipalités et régions autonomes en Chine, et exportés vers plus de 60 pays tels que le Royaume-Uni, la Turquie, le Japon et d'autres. L'entreprise dispose d'une base client et d'un marché conséquents. Les produits de l'entreprise sont très appréciés par les clients nationaux et internationaux.

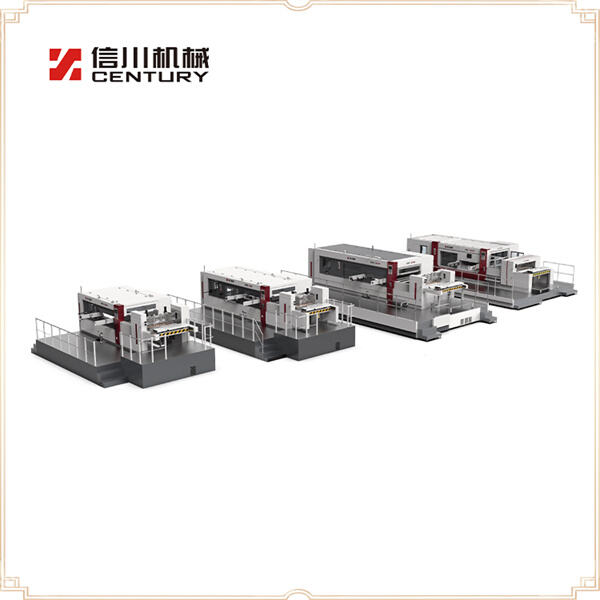

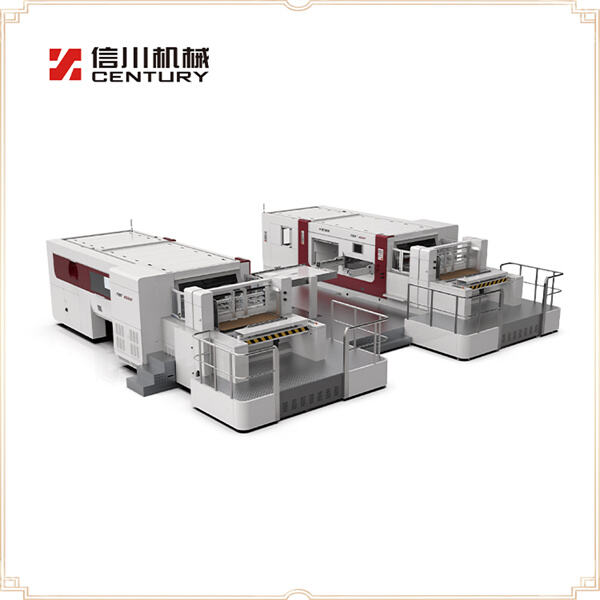

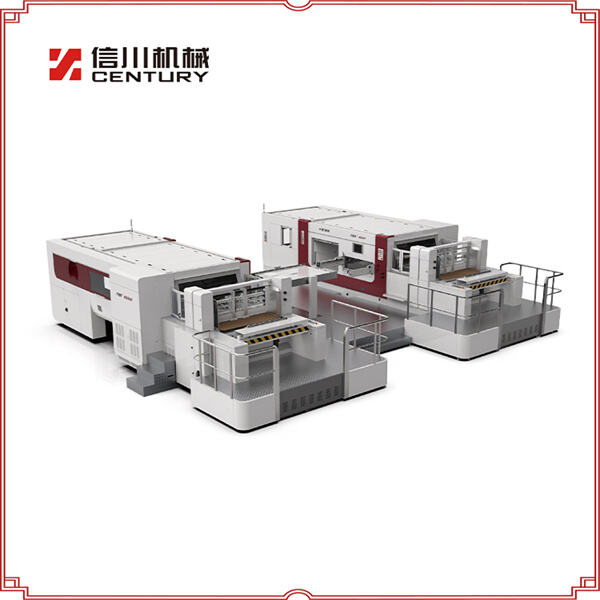

Nous n'avons cessé d'améliorer et d'innover dans nos produits, et nous avons lancé une gamme de produits de découpe de cartons ondulés. La machine à alimentation cassette utilise, par exemple, un mouvement vectoriel "point zéro" pour alimenter le papier sans frottement et sans déplacement. C'est une solution au problème de griffures sur la surface de l'impression. La gamme de produits inclut les modèles 930, 1050, 1150, 1300, 1450, 1620, etc., allant jusqu'à des équipements semi-automatiques, ainsi que les modèles 1050, 1080, 1450, 1650, etc., pour des produits entièrement automatiques, pouvant satisfaire les besoins de production et de processus de clients différents. Les machines de découpe plat de CENTURY Machinery coûtent moins cher que les machines importées. La qualité et les performances du produit sont capables de répondre aux exigences des clients, tout en étant économiques.

Machine de découpe au format plat pour carton ondulé permettant de découper du papier ondulé ainsi que du carton et d'autres matériaux. Elle peut être utilisée à diverses fins et répondre aux besoins de différents clients. Pour garantir la précision de la découpe, l'équipement utilise des matériaux de haute qualité et des technologies de pointe, comme des dents haute résistance et un mécanisme de maintien du papier précis. La pression de découpe est uniforme, avec moins de reprises de plaque, et est à la fois précise et durable. Certains modèles peuvent atteindre une vitesse maximale de 7 500 feuilles par heure. Elle offre une efficacité opérationnelle élevée et peut être combinée avec des équipements prépresse pour améliorer l'efficacité globale de production. La dernière machine de découpe entièrement automatisée et intelligente avec alimentation automatique de papier a réalisé des progrès technologiques en matière d'intelligence et d'automatisation, améliorant considérablement l'efficacité de production, la qualité du carton et la sécurité lors des changements de commandes.