Traditional flatbed press technology has evolved considerably through the cutting of materials into various shapes. This special machine checks it out during the die cutting process. Die cutting involves a sharp punch that presses down on a material to cut it into a desired shape. Since founding CENTURY we have understood the need to utilize the latest technology to get accurate cuts in a timely manner. So, let us take a look at how flatbed press history has evolved into a vital component of die cutting.

The Evolution of Flatbed Press Technology in Die Cutting

But flatbed press technology is not new, it has actually been around for centuries. The earliest flatbed presses were hand operated and these made accurate cuts at the expense of a great deal of hard work. With advancements in technology, machines were designed to expedite the cutting process. These primitive machines paved the way for the flatbed press die cutter technology we use at CENTURY today.

Better Cutting with Upgraded Flatbed Press Technology

Flatbed presses are now more accurate and efficient with new computers and digital technology. Contemporary flatbed press feature computerized systems that allow for very precise cuts, even for complex designs. These modern machines use quality blades and specialized pressure systems to guarantee a clean cut every time! These advancements help us provide our customers with the best die cutting service at CENTURY.

A Brief History of Flatbed Press Technology

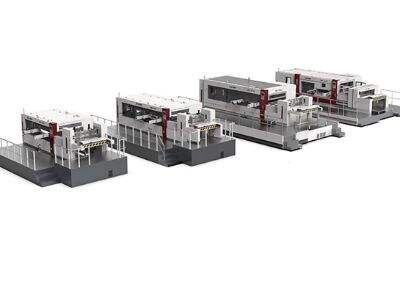

Flatbed press technology has evolved to grow with the industry over the years. The techniques developed new materials and methods for more efficient and precise cutting. At CENTURY, we are constantly striving to advance our flatbed press technology ahead of the competition, and this is the result. We have the best machines available today with all the latest features and software to tackle even the most difficult die cutting jobs.

The Speed of Modern Flatbed Press Technology Makes Cutting Faster and More Accurate

A big advantage of our modern flatbed press technology is that it helps speed up and improve the cutting process. These machines have high-speed blades and precision cutting processes that allow for thousands of cuts per minute. At CENTURY, this speed means we process our customers' big orders quickly and accurately, so they receive their products on time and in great shape.

Revolutionary flatbed printer concepts

New technology in flatbed presses continually changes die cutting. Laser-guided cutting and automatic blade adjustments mean you can create even fine designs to the letter. It is our goal at CENTURY to adopt the latest innovations in flatbed press technology to offer our clients the highest level of service.