Die cutting machines that specialize in flatbed are helpful when trying to best cut shapes out of a variety of materials. In fact, they are widely used in detail place like packaging, printing car making These machines are useful because they allow precise cutting of a range of shapes from different types of material. It has no other real function, but it is designed well for the one job it's meant to do: create shapes as efficient and accurate as possible

Automated flatbed die cutting machines are revolutionizing the way that die cutting is done in a variety of industries. Die cutting was done by hand in the old days. It was a time-consuming process and the effort from workers needed to be heavy. However, CENTURY Second hand die cutting machine have been invented recently and cut the materials now in much quicker time with a minimum number of precision errors. This solution makes time-consuming process that use to be days or even hours in just a few seconds.

There is a great thing with these machines that they can cut multiple materials all together. This capability of producing more products in less time is very critical for companies operating under fast-moving, competitive environments. Moreover, the reductions done by these devices are more accurate and also levelled so there is much less wastefulness. It also means that the final goods appear better and more professional, which is fantastic for businesses

The use of automatic flatbed die cutting machines has increased the rate at which products are delivered, as well as lowered associated costs. As a result machines can be used to cut and process materials at much faster rate, as compared to thrust of manually. For companies, this saves time and money. Moreover, the machines can do a number of things simultaneously – this makes everything work more flexibly and efficiently.

These machines can also be used to perform a record like functions by programming these. This indicates that they can be mounted to reduce various forms, facilitating changing from manufacturing one product to another. CENTURY Die Cutting Machine is used in various sectors and when a company wants to change from cutting one shape to other, the machine can be quickly adjusted for that without many issues. What these machines do is enable businesses to produce increased amounts of items that have better quality in a shorter period.

Flatbed die cutting machines make precise cuts. Cutting a pattern is the hardest task for men, people in olden days| used to find it really hard because before nobody could cut out what looks perfect from material numbers and who managed by hand). But its cutting is much simpler & exact using these machines. These machines are programmed with software that not only leads the mill in cutting, but must also lead you as well. Consequently, this programming is made in such a way that the machines are able to cut only specific shape which helps reduce chances of error and mistakes.

Moreover, these machines are reliable. They are durable and when maintained properly, they will last for many years. This means that companies are able to rely on these CENTURY machines Products for daily material processing without the constant worry of them breaking down or requiring service every other cutting session. They are the perfect solution for business solutions and need stability in work performance.

The company focuses on after-sales support and has set up an Flatbed die cutting machine automatic that can meet customers' needs in a timely manner, and provide customers with professional and efficient technical support and maintenance services, and solve customers' worries. It is the only "Flatbed Die-cutting Machine RD Center" in China named by the China Packaging Federation and the "Shandong Flatbed Technology RD Center" recognized by the Shandong Packaging and Printing Association with the capability to conduct RD with a high level of. We can provide our customers advanced products and solutions by continuously investing in RD and implementing technological innovations, and upgrading product.

Shandong Century Machinery Co., Ltd. was established in 2008. It is an ISO9001 quality management system certified and CE certified enterprise. It is a state-of-the-art provincial company as well as an specialized national "Flatbed die cutting machine automatic" company. It has a high degree of recognition and reputation in the market. It is home to more than fifty skilled scientists, as well as a strong RD department and production team. This guarantees the highest quality and performance. The products offered by the company are sold well in 29 provinces, cities and autonomous regions in China as well as exported to over 60 countries, including the United Kingdom. It has a wide customer base and market base and its products have been accepted by both domestic and international customers.

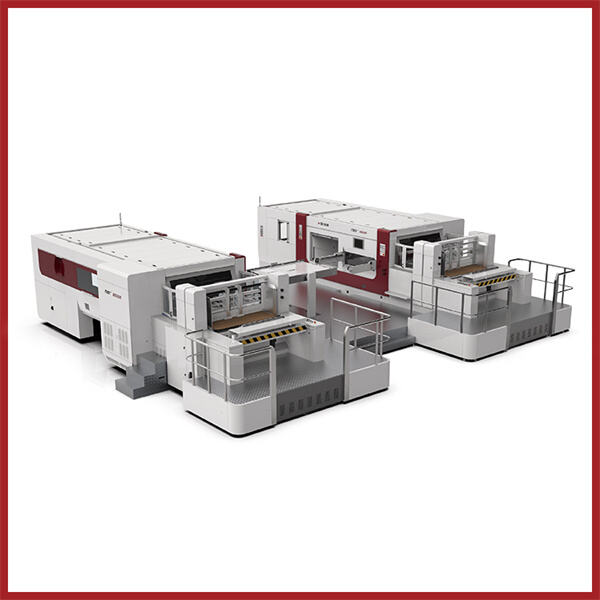

The flatbed die-cutting machine from CENTURY is able to die-cut not just Flatbed die cutting machine automatic however, it can also cut cardboard and other materials. It has a wide range of applications and can meet the needs of different customers. The equipment is built with the latest technology and high-quality components, such as high-strength teeth and precise paper gripping mechanisms which ensures the die-cutting accuracy of paper. The pressure used to cut paper is uniform, with less plate re-printing and is precise and durable. Some models can attain 7500 sheets per hour, and have excellent efficiency. It can be matched with pre-press equipment to improve the overall efficiency of production. The new front-edge paper feeding fully automatic intelligent die-cutting machine has achieved intelligent and automated technological advances in production efficiency, the quality of cardboard, and safety guarantees significantly improving the efficiency of production for order change.

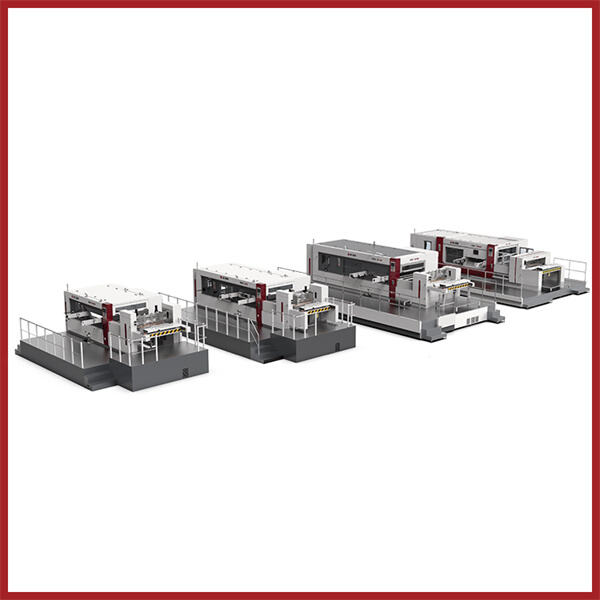

Flatbed die cutting machine automatic been continually improving and innovating our products and have released a range of unique products. The cassette-type paper feed machine, for example, uses vector "zero point" motion to feed the paper using zero friction and with no displacement. This helps solve scratching problems on the surface of the print. The range of products include 930, 1050, 1160, 1300, 1450, and 1620. to semi-automatic equipment, and 1050, 1080 1450, 1650 and so on. for fully automatic products that can meet the scale of production and processing demands of different clients. CENTURY Machinery flatbed die-cutting machines are cheaper than imported products. However, the product quality and performance also meets the needs of customers, with a high cost performance.