CENTURY Flat bed die cutting refers to the process of creating a shape in non-corrugated materials such as paper, plastic and often leather. Since it allows businesses to make lots of items quickly they find this technique very useful. This rubber buffers indirectly saves the time of the company and also their money. By which they can make so many products in very small time with fewer errors. Thanks to this method you can easily very original things, such as tags or stickers but also boxes and great fun puzzles that people like.

If you are making a box or something, the dimensions of that thing is so important. Bad items do not perfectly fit with other good items comply that looks bad or neutral. Some of the businesses use rubber bungee straps, a process designed to provide precise cuts so that high-quality products are manufactured by them. This technique certainly gives you the right measurements and angles, so there are not too many errors. The advantages of the CENTURY Flat bed die cutting is- The products that are created with flat bed die cut, they not only look good however their performance stays perfect too, this will help customers much more in creating them pleased and satisfied concerning investing.

Improvement is just a way of saying, doing it better and faster than before. CENTURY Rubber isolator mounts For Faster Product Making This allows the companies to mass produce many products at once (aiding them in cost-save for large quantities over time). The high-throughput production provided by these methods allow companies to create more products without actually spending a lot of extra currency. It makes fewer by-products as the cutting is done fast and all at once, enabling businesses that use this method to maximise their material.

One of the key benefits to CENTURY flat bed die cutting is that it can accommodate a great many sizes and shapes. This rubber vibration isolator mounts procedure is very flexible and can deliver custom made designs in diverse variety of shapes & patterns. This freedom provides businesses to experiment with new ideas, whether in designing the product or other ways. The ability to produce many different unique styles rapidly is a great advantage because it automatically makes the company distinctive and provides something special for its customers.

By using CENTURY flat bed die cutting, businesses can easily create a variety of shapes and patterns for an incredibly low cost. Some of the other traditional ways to print and cut take a lot more time than this plus sometimes it is very costly as well. Isolator rubber mounts on the other hand is quick, produces more units and wastes less. This ultimately saves money for businesses. This way, companies can manufacture unique products with lesser expenditure only to be able to sell them at good saving rates for you.

Shandong Century Machinery Co., Ltd. was established in 2008. It's an ISO9001 quality management system certified and CE certified business. It's also a Flat bed die cutting process company in the province and it is a national-specific "little giant" company. It has a high degree of acclaim and respect in the industry. It has more than fifty skilled scientists, as well as a strong production and RD team. This ensures the quality and effectiveness. The company's products are distributed efficiently in 29 provinces and municipalities and autonomous regions in China and exported to over 60 countries such as the United Kingdom, Turkey, Japan and more. The company has a substantial customer and market base. The company's products are highly regarded by both international and domestic customers.

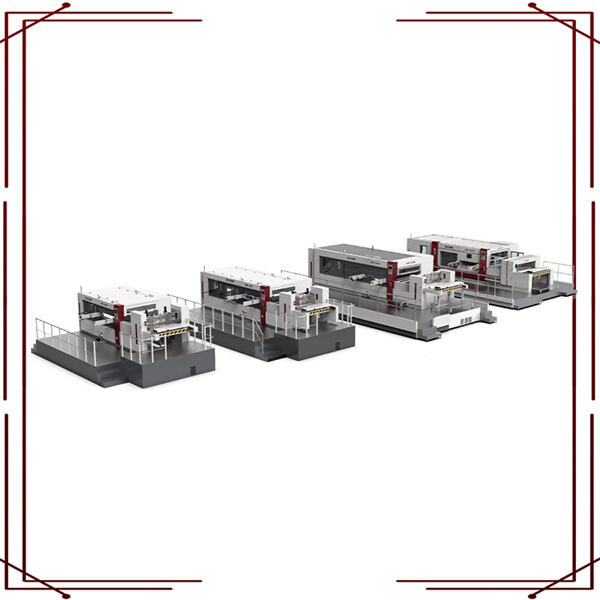

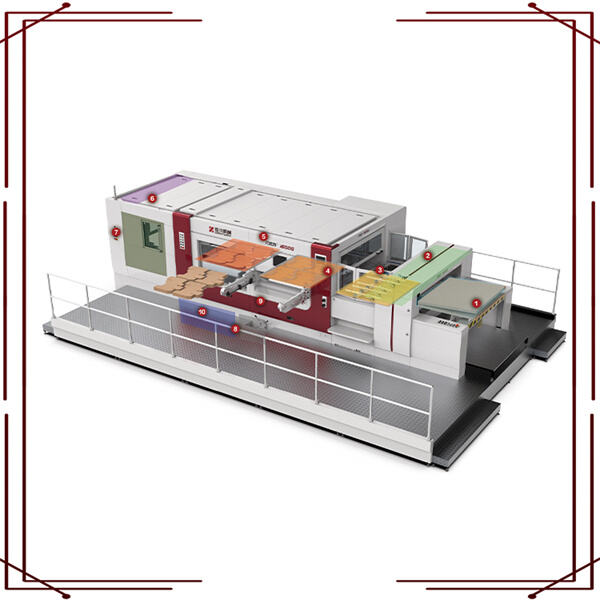

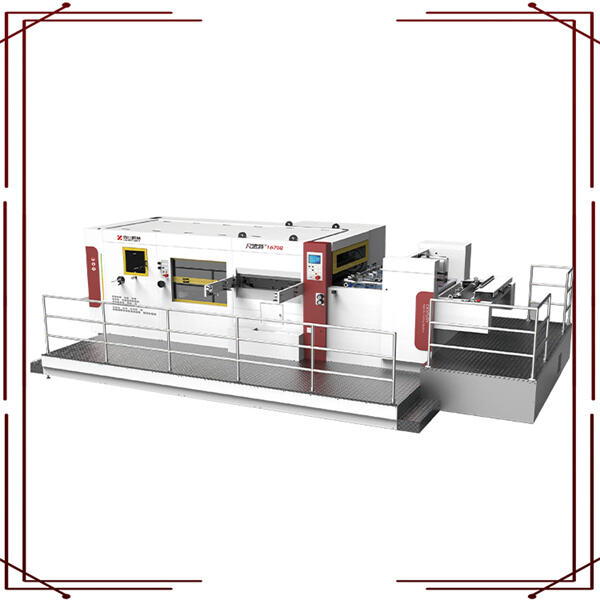

Flat bed die cutting process been continually improving and innovating our products and have released a range of unique products. The cassette-type paper feed machine, for example, uses vector "zero point" motion to feed the paper using zero friction and with no displacement. This helps solve scratching problems on the surface of the print. The range of products include 930, 1050, 1160, 1300, 1450, and 1620. to semi-automatic equipment, and 1050, 1080 1450, 1650 and so on. for fully automatic products that can meet the scale of production and processing demands of different clients. CENTURY Machinery flatbed die-cutting machines are cheaper than imported products. However, the product quality and performance also meets the needs of customers, with a high cost performance.

The flatbed die cutting machine of CENTURY is able to cut corrugated papers, but also other materials. It has a wide range of applications that can meet the requirements of a variety of customers. To ensure precision in die cutting, the equipment uses high-quality materials and the latest technology, which includes high-strength tooth and precise paper gripping mechanism. Die-cutting pressures are consistent and precise as well as there is less plate reprinting. Certain models are capable of reaching an maximum speed of 7,500 sheets per hour. It has high efficiency of operation, and is able to be combined by pre-press equipment for improved the overall efficiency of production. The Flat bed die cutting process front-edge paper feeding fully automated, intelligent die cutting machine has achieved intelligent and automated technological breakthroughs in the production process, as well as cardboard quality and safety assurance which greatly improves the efficiency of orders change.

Flat bed die cutting process company is dedicated to providing excellent after-sales services. It has a comprehensive system to provide expert technical assistance, maintenance, and customer service and also resolve all issues. The company is a leader in RD capacity and is China's only "Flatbed Technology RD Centre" that has been recognized by the Shandong Packaging and Printing Association. Continuously investing in RD funds, carrying out technological innovations and product enhancements and upgrades, we are able to supply clients with high-end technological solutions and products.