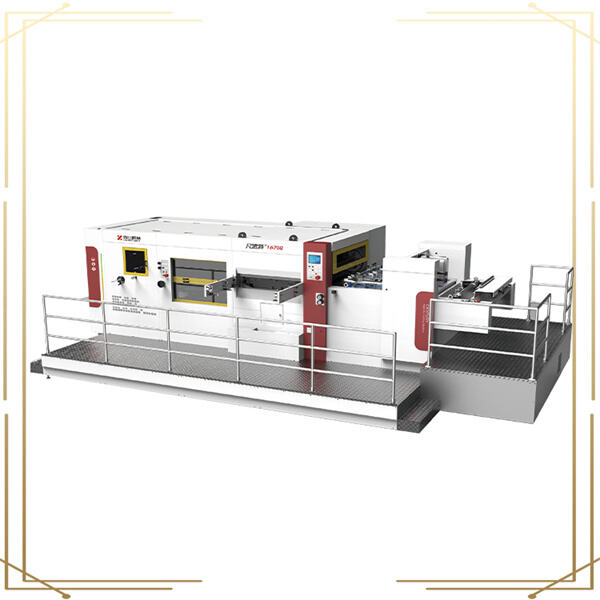

Die-cutting machines are unique tools that can create specific cuts and shapes from a variety of materials. These machines are utilized widely in the factories where they manufacture various things like boxes, signs, labels etc, same with the CENTURY Semi automatic die cutting machine. A flat bed die cutting machine is a type of die cutter. It is known to be a powerhouse for so many different kinds of jobs.

Flat bed die cutting machines are known to be most advantageous and correct. Flat bed die cutters are also not limited to certain materials in the way other types of machines that cut material are limited, just like the CPU Intelligent Packaging Line. These materials include (but are not limited to) paper, cardboard, plastic, foams etc. Which makes them perfect to engrave unique shapes and forms. Here is how they appear perfect and straight cuts are used. So that when you pull it, the finished product is what you want. There are many different types and sizes of flat bed die cutting machines are used in all types of jobs.

The possibilities with flat bed die cutting machines are almost endless. It can cut detailed designs and shapes, making it great for creating custom packaging or labels, along with the Second hand die cutting machine. It provides businesses with the ability to produce differentiated products which attracts attention. A flat bed die cutting machine has many different uses across industries. Car manufacturing, Packaging and Print industry for instance. Hobbyist crafters enjoy them as well. Makers adore these machines, since they simplify the development of unique design for their tasks, it could be cards or present decorations and also other creative items.

Flat bed die cutting machines have the ability to produce perfect cuts every time and this is one of the biggest advantages of using them, just like the CENTURY Automatic die cutting machine. They do this via modern cutting tools and with the help of state-of-the-art computer software. When using these machines, all cuts are identical, thus if you have to cut many an identical piece each will be the same as the other. These devices replace the tedious and occasionally messy manual pruning or hand trimming process. For companies that need to produce a lot of items quickly, this makes flat bed die cutting the more intelligent business solution as it not only saves time but also reduces waste.

Flat bed die cutting machines are valuable pieces of equipment that allow companies to create more efficient production processes and save on costs as well as its CENTURY New Material. The tools remove the material very fast and accurately, allowing them to be used in a range of applications across multiple industries. Century has top-notch flat bed die cutting machines ideal for companies aiming to enhance their production and make some interesting design. Flat bed die cut machines are versatile, precise and cost-efficient and they are becoming indispensable in the way that businesses make their products.

The company is dedicated to providing top after-sales support. It has a comprehensive system for providing professional technical assistance, maintenance and customer support and also resolve any problems. It is the only "Flatbed Die-cutting Machine RD Centre" in Flat bed die cutting machine applications awarded by the China Packaging Federation and the "Shandong Flatbed Technology RD Center" named by the Shandong Packaging and Printing Association and boasts an impressive RD capability. Constantly investing in RD funds, carrying out technological innovations and product enhancements We can supply customers with cutting-edge technological solutions and products.

Shandong Century Machinery Co., Ltd. was established in 2008. The enterprise is CE-certified and ISO9001 certified. It is a state-of-the-art regional enterprise and a specialized national "little giant" company. It enjoys a high level of recognition and a good reputation within the business. The company has more than 50 highly skilled scientific researchers and a strong technical RD and production team to ensure the quality and efficiency of their products. The company's products are sold well in 29 provinces, municipalities, and autonomous regions of China and exported to more than 60 countries such as the United Kingdom, Turkey, Japan and more. The company has a vast customer base and market base and its products are accepted by both domestic and Flat bed die cutting machine applications.

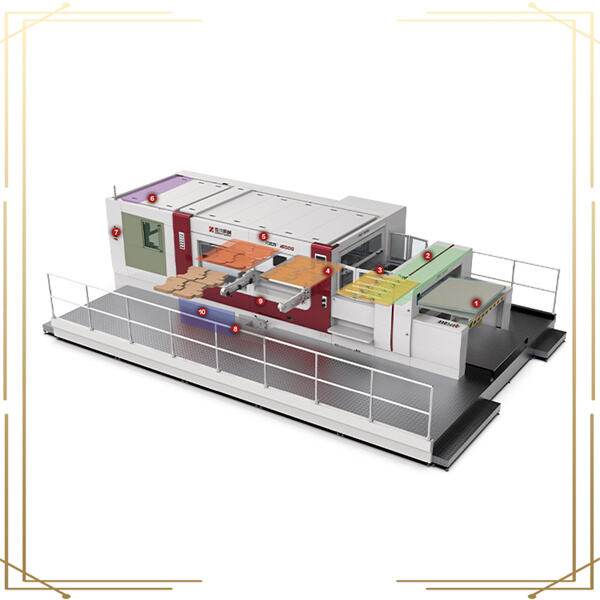

The flatbed die cutting machine from CENTURY is able to cut corrugated papers, but other materials. It can be utilized for a range of purposes and meet the needs of many clients. To ensure precision in die cutting this equipment is constructed with high-quality materials and modern technology, including high-strength tooth and a precise mechanism for gripping paper. The pressure used to cut paper is uniform which means that there is less Flat bed die cutting machine applications of plates and is also precise and long-lasting. Certain models can achieve an maximum speed of 7,500 sheets per hour, with high efficiency of operation, and can be paired with pre-press equipment to enhance the overall efficiency of production. The latest front-edge paper-feeding completely automated intelligent cutting die is a breakthrough technological advancement that has been fully designed to be automated and has improved production efficiency as well as the quality of cardboard used and security.

We've been constantly improving and innovating our products, and have Flat bed die cutting machine applications a number of unique products. The cassette-type feed machine employs, for instance, a the vector "zero point" motion to feed the paper using zero friction, and no displacement. This helps solve scratching issues on the printed surface. The range of products includes 930, 1050, 1150, 1300, 1450, 1620 etc. for semi-automatic products as well as 1050,1080, 1450, 1650, and so on. for fully automatic products and can be adapted to the scale of production and process demands of different clients. CENTURY Machinery flatbed die-cutting machines cost less than imported machines. The quality and performance of the product can satisfy the requirements of customers and is also cost-effective.